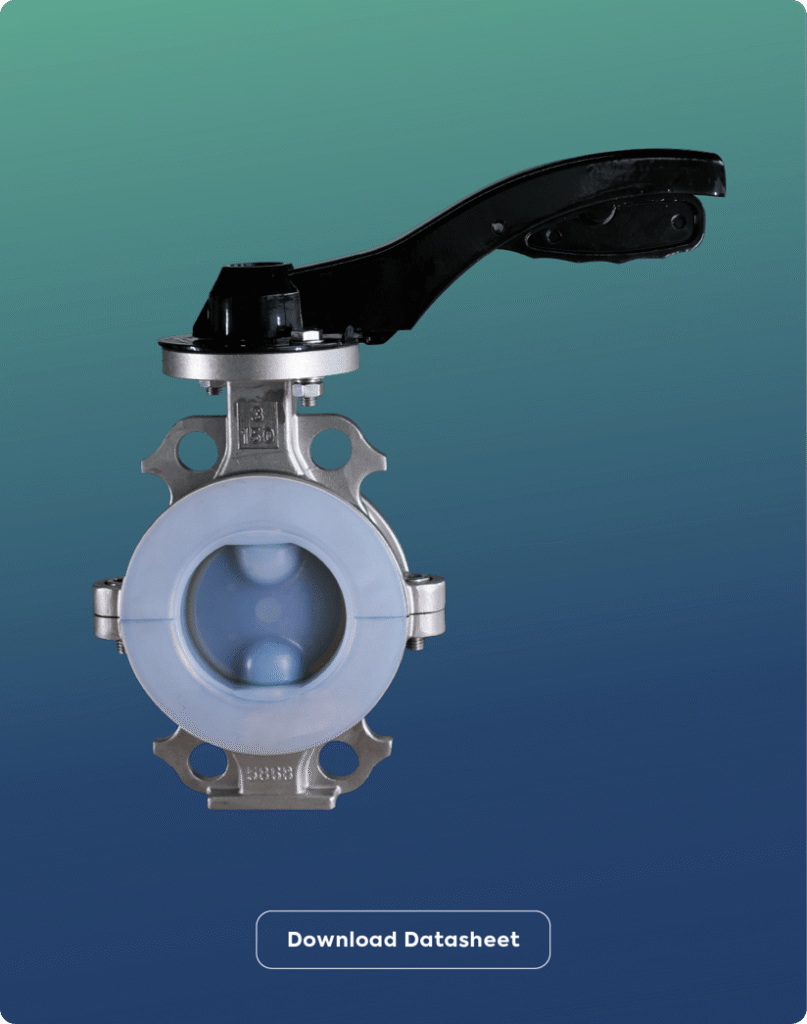

Butterfly Valve

BU26 Series

Engineered for corrosion resistance and high-purity isolation.

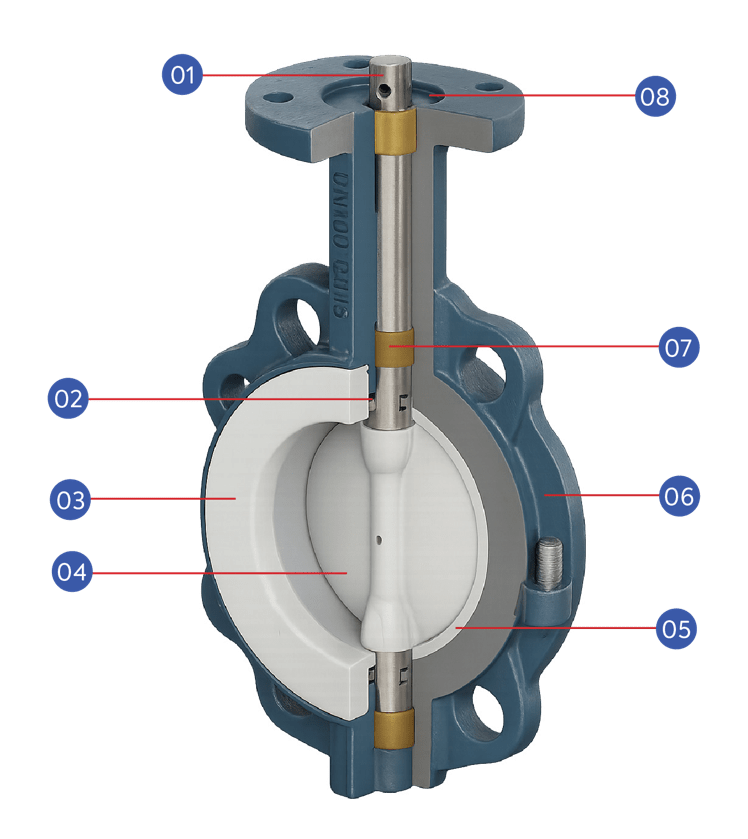

What’s Inside Matters

Engineered for Performance

Its fully PFA-lined design delivers reliable shut-off, stable torque performance, and extended service life in demanding chemical, steam, and high-temperature environments.

01. Shaft

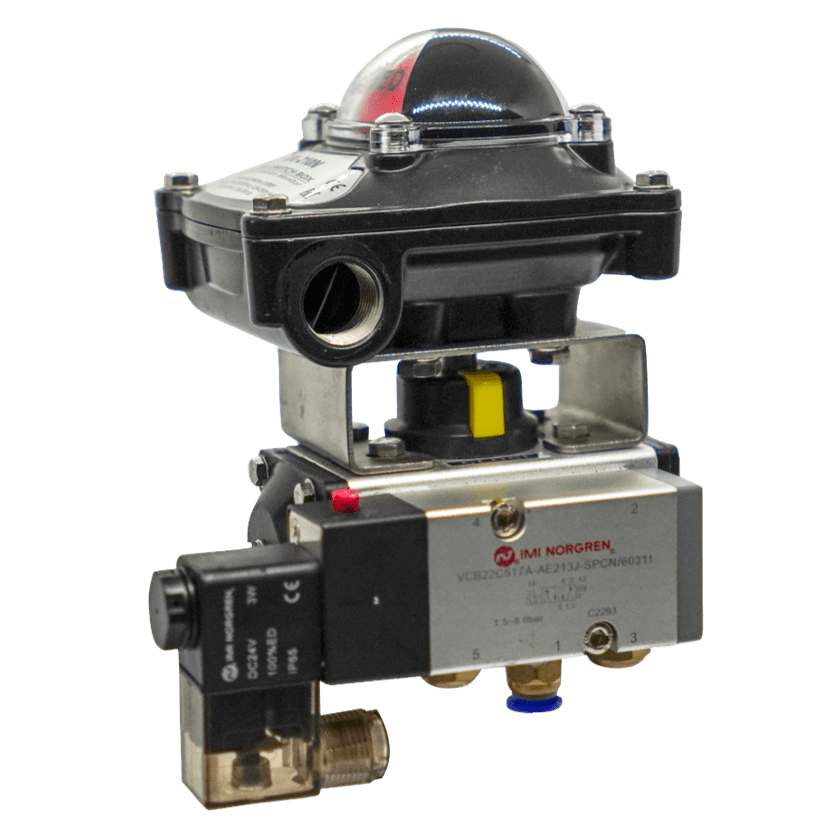

Square-type stem head design enables easy adaptation to automated actuation.

02. Belleville Washer

The specially designed elastomer washer applies live loading to maintain constant pressure on the body lining. Fluoroelastomer materials reduce deformation caused by continuous temperature variation.

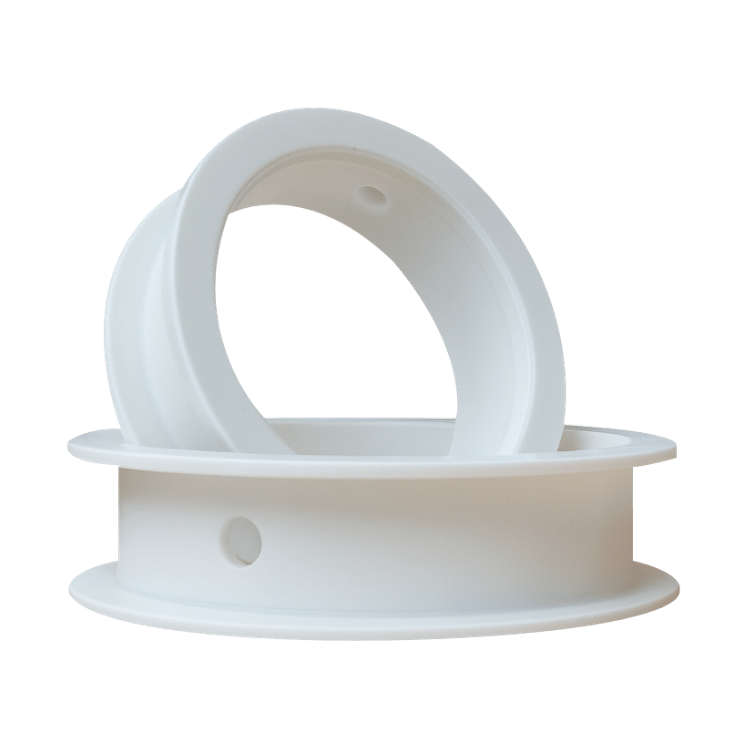

03. Seat

Moulded liner is machined to deliver low torque and minimise wear on contact surfaces.

04. One-Piece Disc

The disc features a spherically machined and hand-polished edge to reduce torque and enhance sealing performance.

05. Elastomer Back-up

Matching the width of the disc edge, this back-up element locks into the body groove. It increases resilience to the body liner and provides a bubble-tight seal.

06. Body

Two-piece split body with epoxy coating resists the effects of atmospheric corrosion.

07. Stem Bearings

Bronze, PTFE, or stainless steel bearings maintain shaft alignment. Self-lubricated design reduces shaft loading.

08. ISO 5211 Mounting Flange

Universal mounting dimensions support a wide range of actuators. Direct mounting of several actuation types is possible without adapters.

BU26 Series

Engineered for corrosion resistance and high-purity isolation, the BU26 Series excels in aggressive media, thermal oil systems, and ultrapure process applications.

Specifications

Body Type

Wafer, Lug

Body Materials

Ductile Iron GGG40

Carbon Steel 1.0619

Stainless Steel 1.4408

Liner

PFA / PTFE / RTFE / TFM

Working Pressure

PN10

PN16

ANSI 150

JIS 10K

JIS 16K

Face to Face

API609

EN558-120 Series

ISO5752

DIN3202K1

Top Flange

ISO 5211

Flange Drilling

BS EN1092

JIS B2220

ASME Class 125 / Class 150

Stem Top

Square Top Flange

Key Features

- Square-type stem design allows direct mounting to various actuators

- Live-loading Belleville washer maintains liner sealing pressure under temperature changes

- Moulded seat liner ensures low torque and reduces wear on sealing surfaces

- One-piece disc with polished edge enhances sealing and reduces torque demand

- Elastomer back-up ring locks into liner groove to improve seal reliability

- Two-piece split body with epoxy coating offers excellent corrosion resistance

- Stem bearings in PTFE, bronze, or stainless ensure alignment and minimise wear

- ISO 5211 flange allows direct actuator mounting without the need for adapters

Performance Testing

Hydro Test

Air Leakage Test

Application Versatility

Built to Perform Across Industries

Our valves are engineered to deliver consistent performance across a wide range of demanding industrial environments.

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

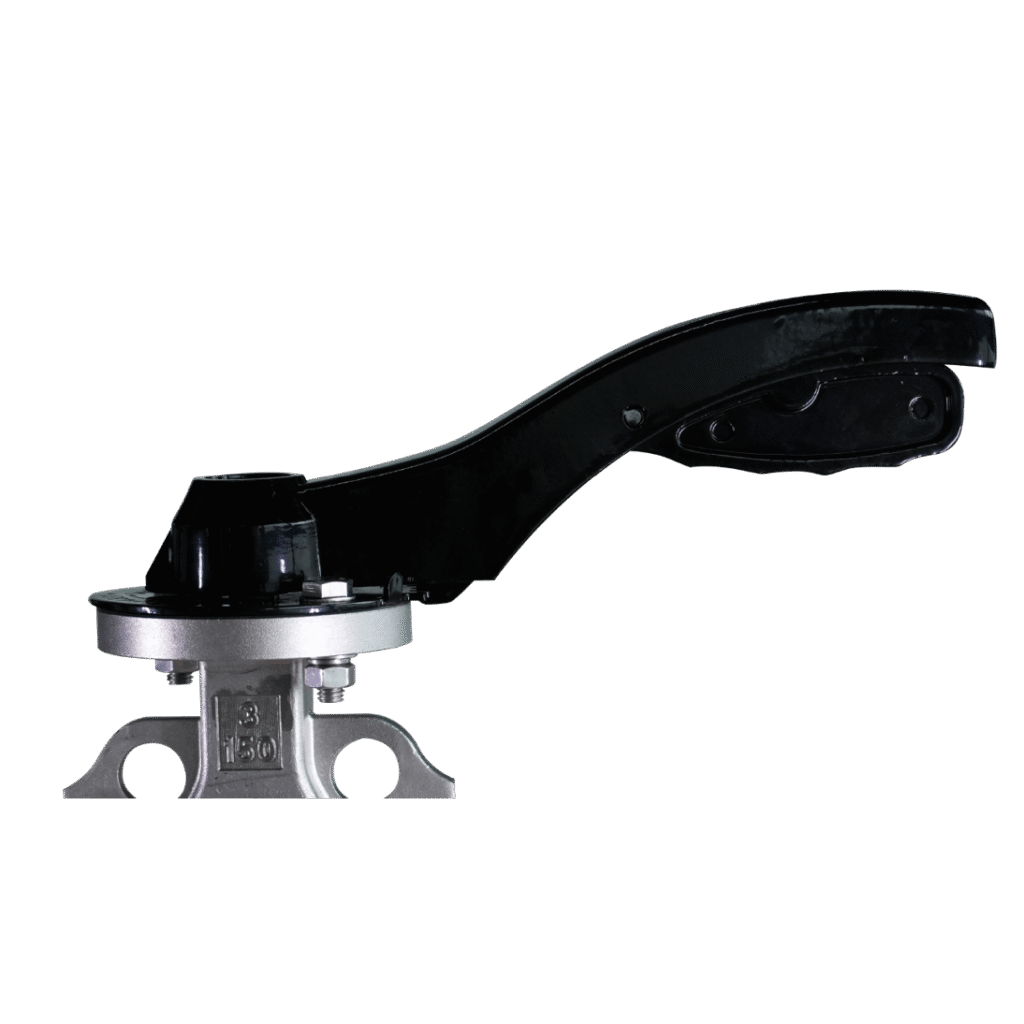

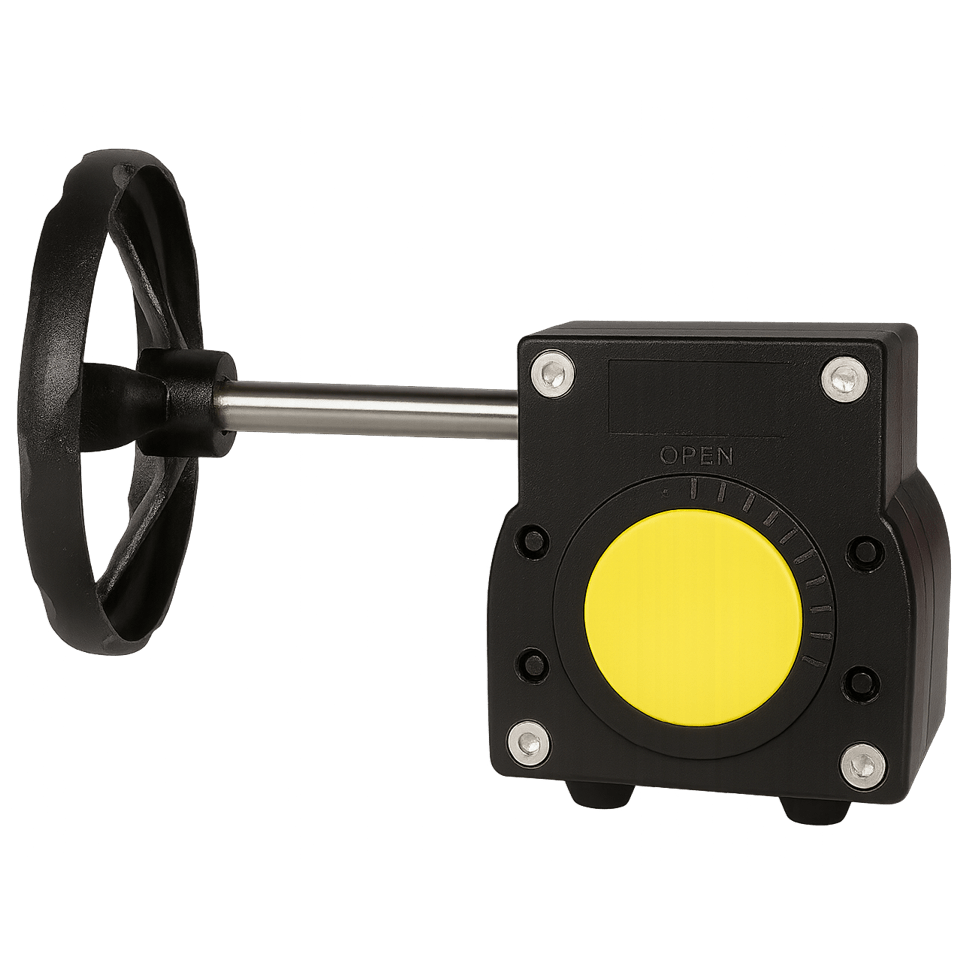

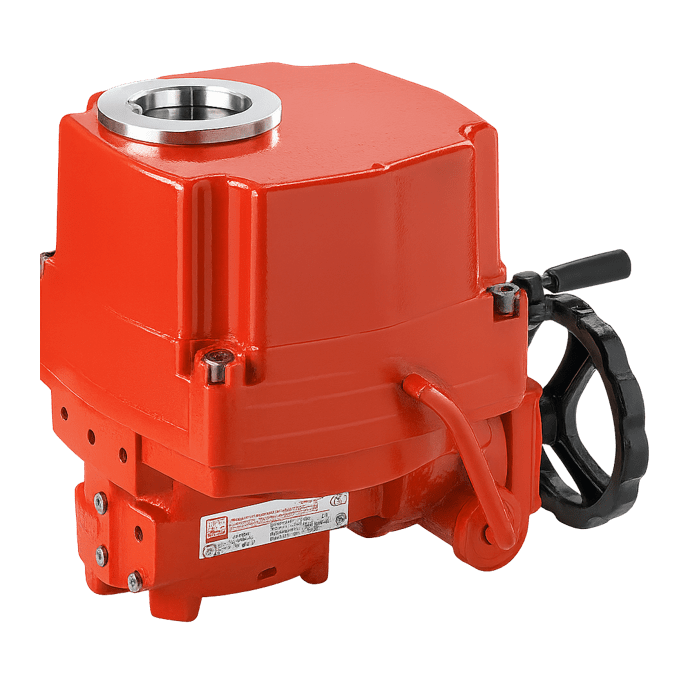

Available Options

Enhance Your Valve Functionality

Choose from a range of accessories designed to extend performance, simplify operation, and suit specific installation needs.