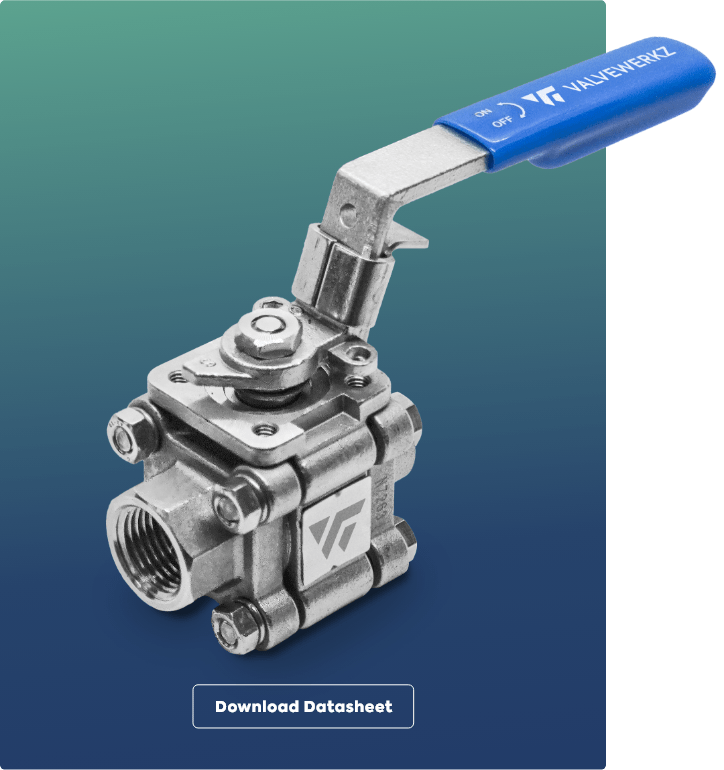

High Performance Valve

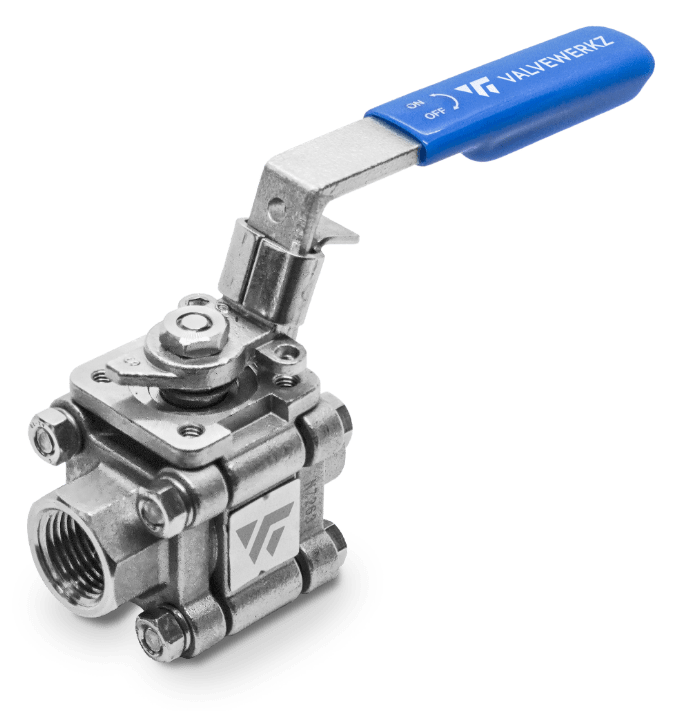

80 Series Ball Valve

Engineered for high performance and process-critical applications.

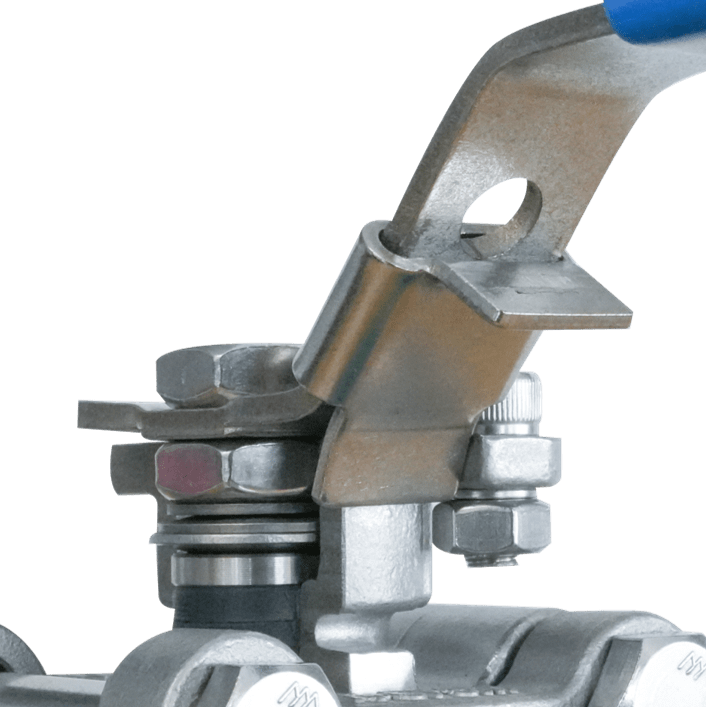

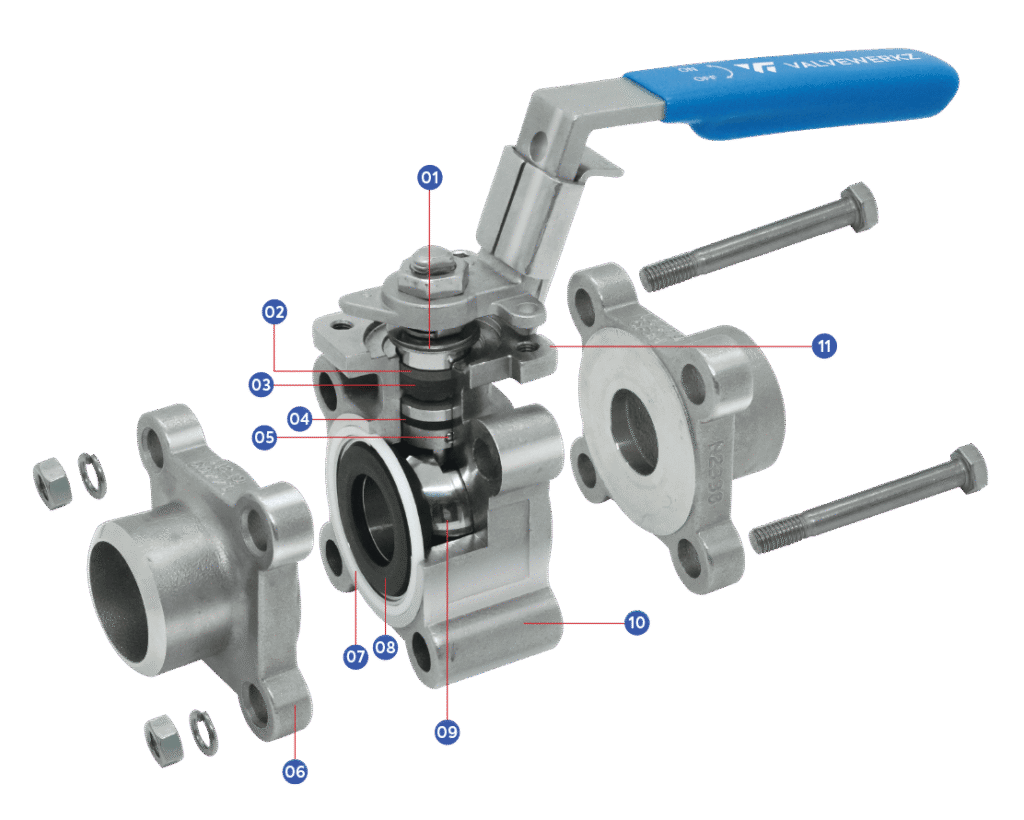

What’s Inside Matters

Engineered for Performance

The 80 Series Ball Valve is built for high performance and process-critical applications where durability, precision, and reliability are paramount.

Part Name

1. Belleville Washer

2. Bushing

3. V-Ring Packing

4. Upper and Lower Stem Seal

5. Dual Anti-Static Device

6. End Cap

7. Seat

8. Body Gasket

9. Ball

10. Body

11. ISO5211 Mounting Pad

What’s Inside Matters

Engineered for Performance

Featuring advanced seat materials, pressure-rated construction, and optional metal-to-metal sealing, this series is ideal for oil & gas, chemical, and power generation systems. It supports automation and complies with stringent process standards.

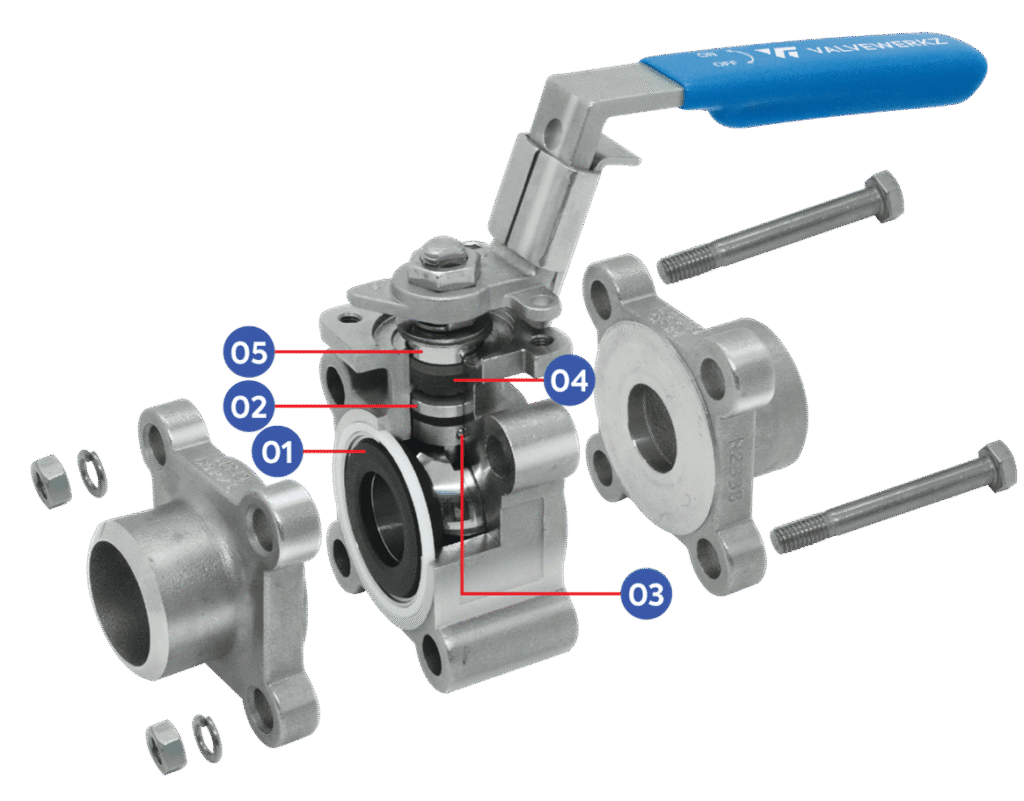

01. Low Operating Torque, Cold Flow Control Design, Extended Service Life

Elastic seat cushioning ensures smooth, uniform ball rotation without jamming.

Trimmed and wrapped seat structure supports non-contact areas, preventing cold flow deformation and enabling high-pressure performance.

Long pre-compression stroke in the elastic seat provides high wear compensation for greater durability.

02. Blow-Out Prevention

Integral shoulder design on the stem prevents blow-out and leakage.

03. Anti-Static Protection (Dual Anti-Static Device)

Dual anti-static design reduces safety hazards from static electricity.

04. Effective Stem Sealing

V-ring packing and a primary pyramidal stem seal provide reliable stem sealing.

05. Self-Adjusting Packing

Pre-loaded Belleville washers automatically adjust packing, reducing the need for re-tightening in low-leakage applications.

80 Series

Engineered for durability and precision control, the 80 Series delivers leak-tight performance under demanding conditions.

Specifications

Design

3-Piece Body

Full Bore / Reduced Bore

Body Material

Carbon Steel

SS316

Ball Material

SS316

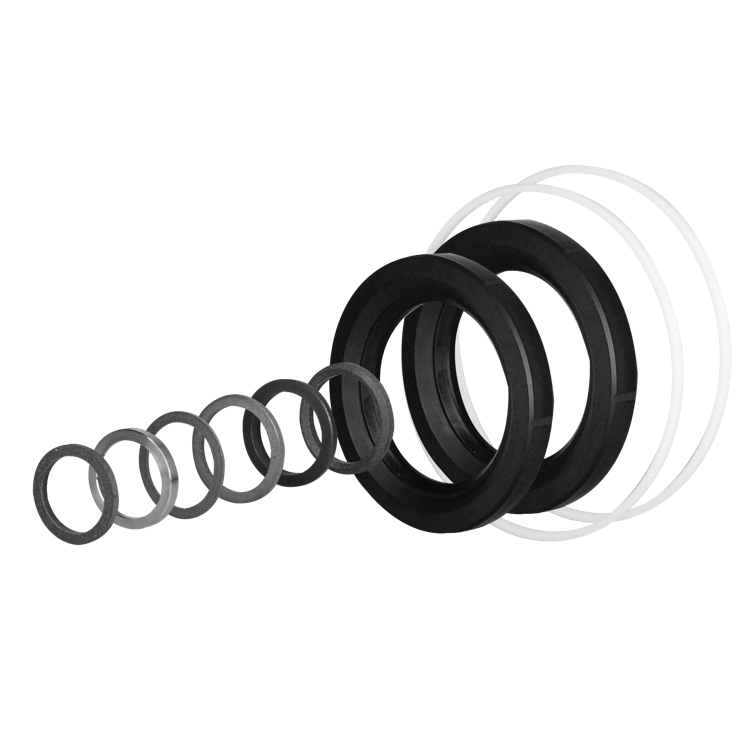

Seat Material

25% Carbon filed PTFE

50% SS filled PTFE

PEEK

Connection

Threaded End (¼” – 4”)

Socket Weld End (¼” – 4”)

Butt Weld End (¼” – 10”)

Size

DN8 (¼”) to DN100 (4”)

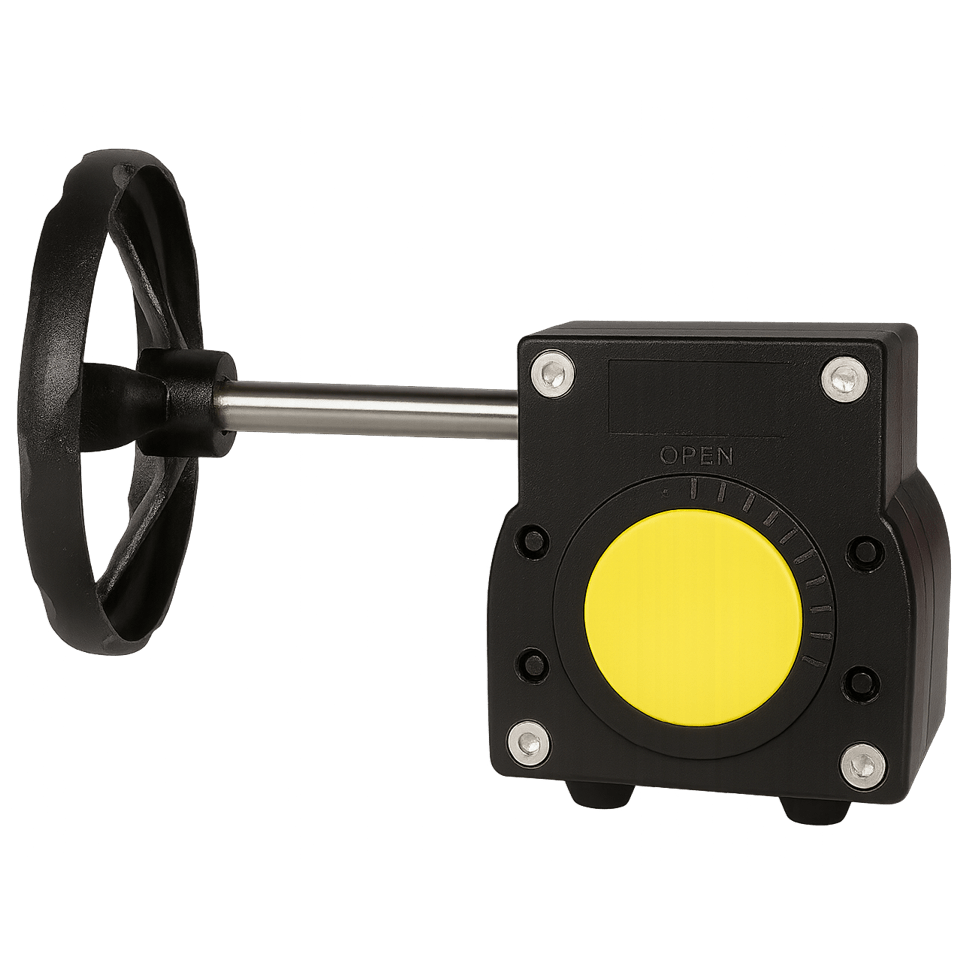

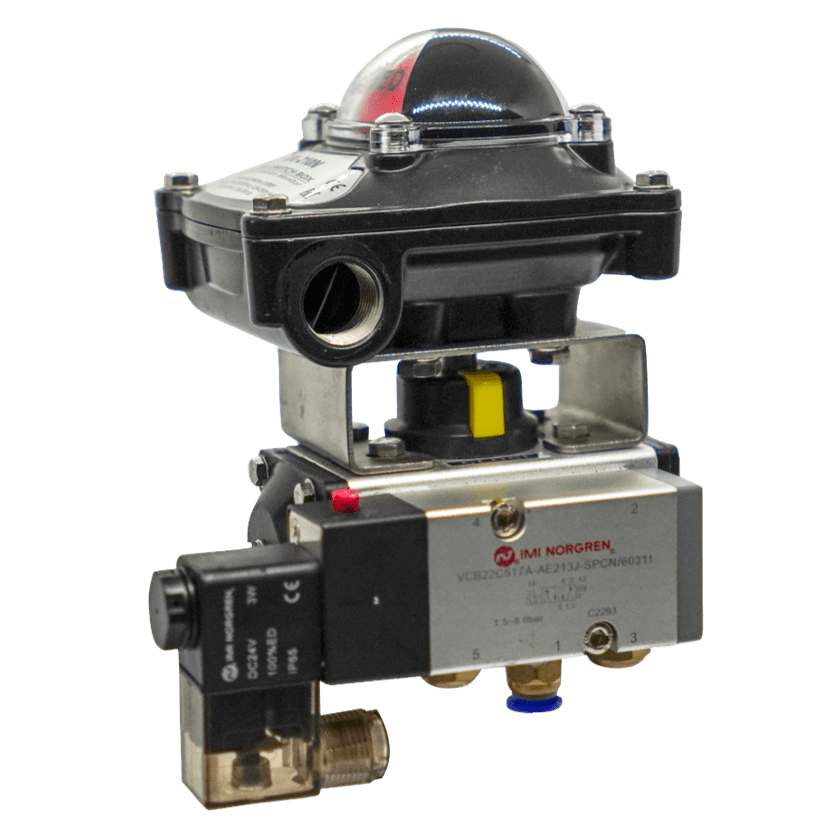

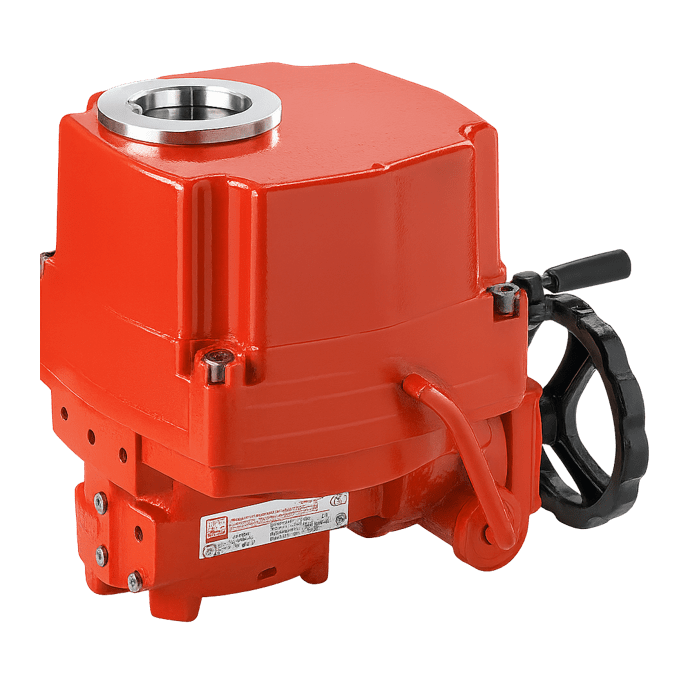

Automation Option & Accessories

Pneumatic Actuator

(Single Acting / Double Acting)

Electric Actuator

Flow Capacity

Cv = 7 to Cv = 2000

Pressure Rating

PN100 ¼” – 1”

PN64 1 ¼” – 2”

PN50 2 ½” – 4”

PN16 5” – 10”

Key Features

- Superior Live Loaded Packing System (V-ring Packing)

- ISO 5211 Mounting Pad (Bracket Required)

- Blowout-Proof Stem

- Dual Anti-Static Devices

- Low Operating Torque

- Reliable Sealing

- Extended Service Life

- Cold Flow Control Design

Performance Testing

Shell Test

Seat Test

Hydro Test

Anti-static Test

Application Versatility

Built to Perform Across Industries

Our valves are engineered to deliver consistent performance across a wide range of demanding industrial environments.

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Available Options

Enhance Your Valve Functionality

Choose from a range of accessories designed to extend performance, simplify operation, and suit specific installation needs.