High Performance Valve

81FS Series Ball Valve

Engineered for high performance and process-critical applications.

What’s Inside Matters

Engineered for Performance

Every part is designed for durability, precision, and reliability under pressure. From anti-static safety, fire safety to stem seal integrity, each component plays a critical role in long-term valve performance and system safety.

Fire Tested To API 607 Valvewerkz 81FS Soft-Seated 3pc Ball Valve

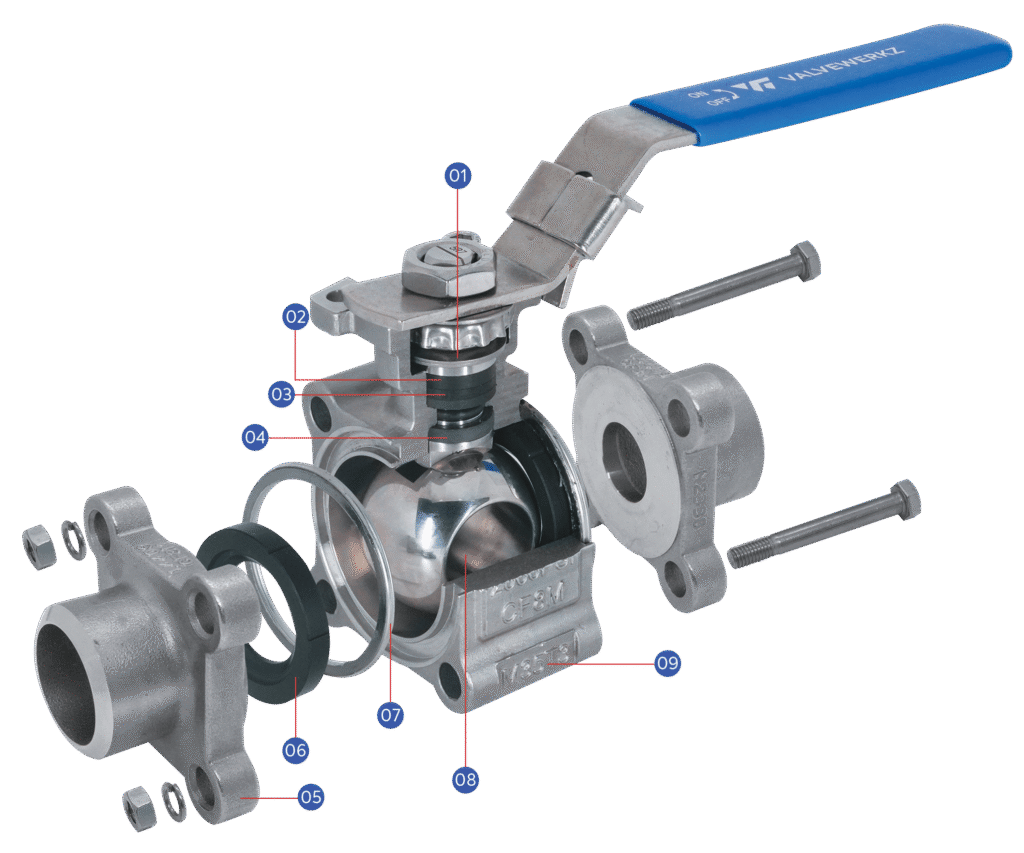

Part Name

1. Belleville Washer

2. Bushing

3. V-Ring Packing

4. Upper and Lower Stem Seal

5. End Cap

6. Seat

7. Body Gasket

8. Ball

9. Body

What’s Inside Matters

Engineered for Performance

Constructed with full stainless steel and fire-safe features, it provides robust sealing and long-term reliability in aggressive environments. Designed for critical isolation in industries such as oil & gas, chemical processing, and power plants, the 81FS excels under demanding pressure and temperature conditions.

Fire Tested To API 607 Valvewerkz 81FS Soft-Seated 3pc Ball Valve

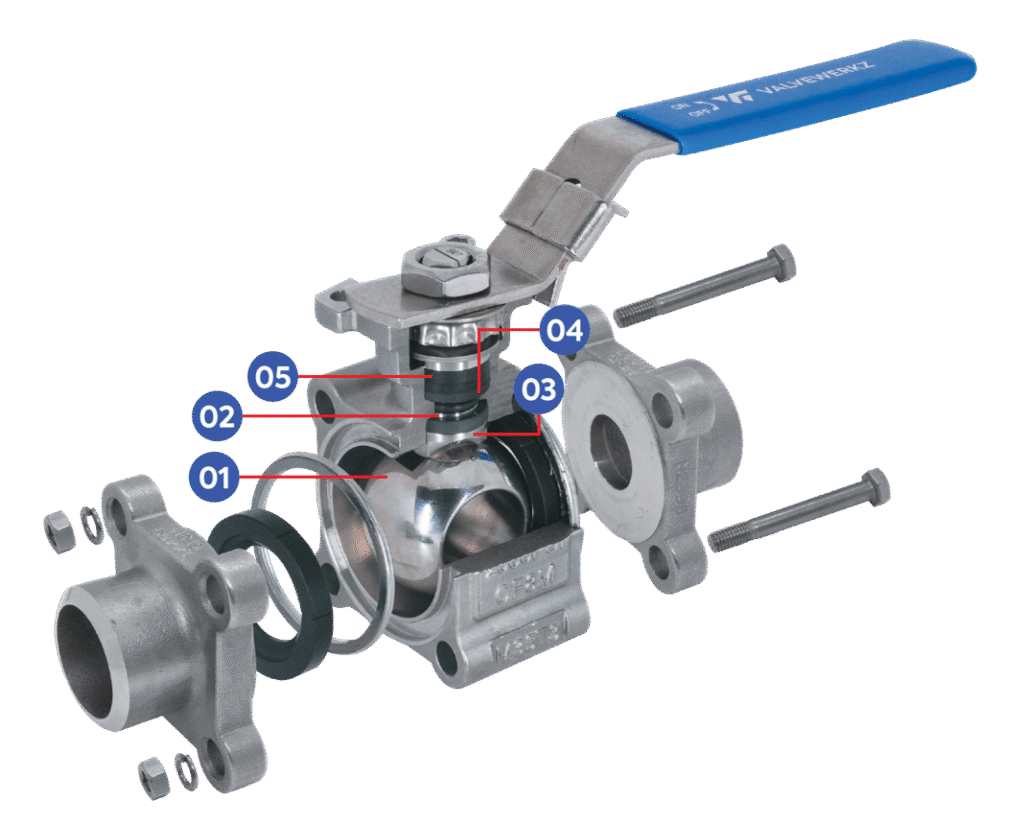

01. Fire-Safe Design for Leakage Prevention

In the event of a fire, soft seats are destroyed, allowing the ball to move downstream and create a secure metal-to-metal seal against the end cap’s fire-safe lip, preventing through leakage.

02. Blow-Out Prevention

Integral stem shoulder design prevents blow-out and leakage under extreme conditions.

03. Anti-Static Protection (Dual Anti-Static Device)

Dual anti-static system reduces the risk of safety hazards from static electricity.

04. Reliable Stem Sealing

V-ring packing combined with a primary pyramidal stem seal ensures dependable sealing performance.

05. Fire-Resistant Stem Seal

Grafoil packing and seal arrangement maintain integrity under fire conditions for enhanced safety.

81FS Series

The 81FS Series Ball Valve is a fire-safe, precision-engineered solution designed for high performance and process-critical operations.

Specifications

Design

3-Piece Body – Fire Safe

Full Bore / Reduced Bore

Body Material

Carbon Steel,

SS304

SS316

Ball Material

SS316

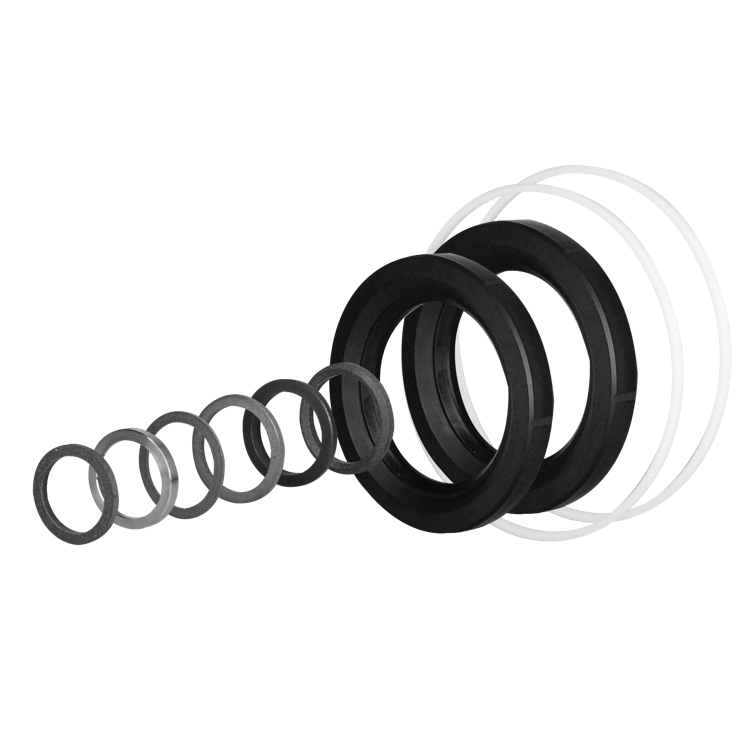

Seat Material

CPTFE

TFM4215

TFM4215 + 50%SS

PEEK

Connection

Threaded End (¼” – 4”)

Socket Weld End (¼” – 4”)

Butt Weld End (¼” – 10”)

Size

Full Bore DN8 (¼˝) to DN100 (4˝)

Reduced Bore DN15 (½”) to DN100 (4˝)

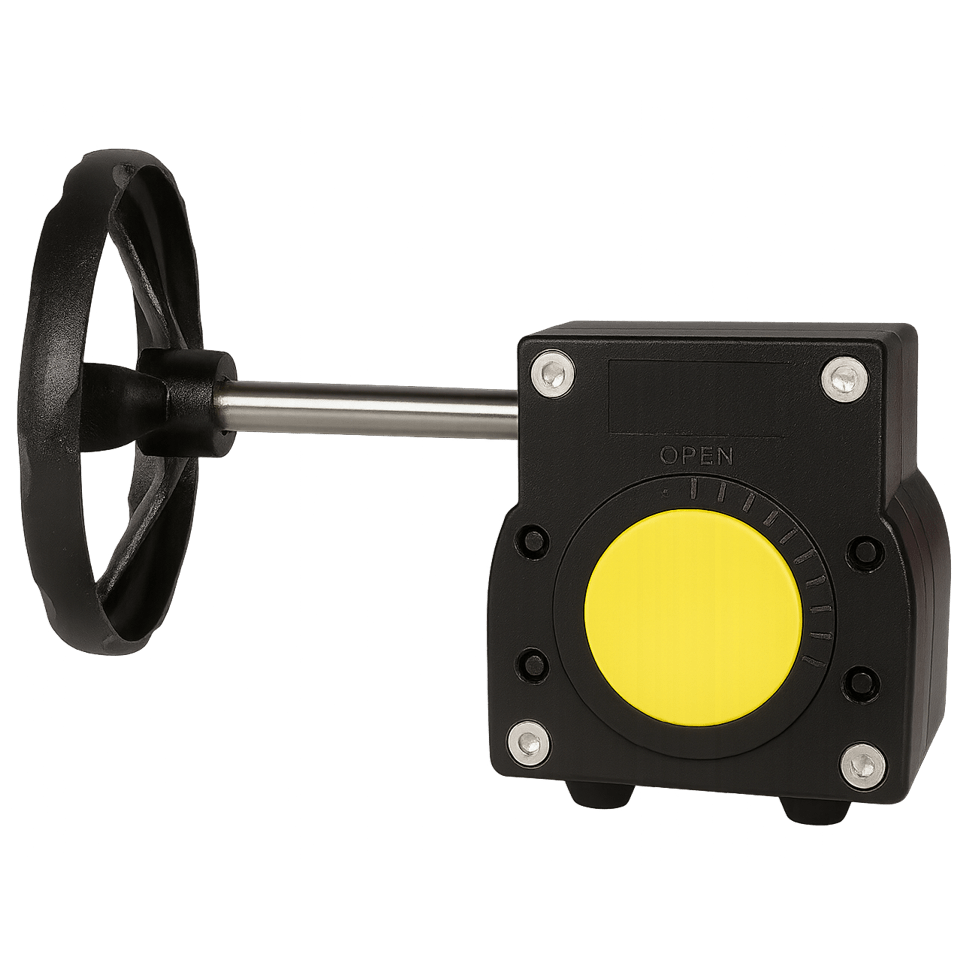

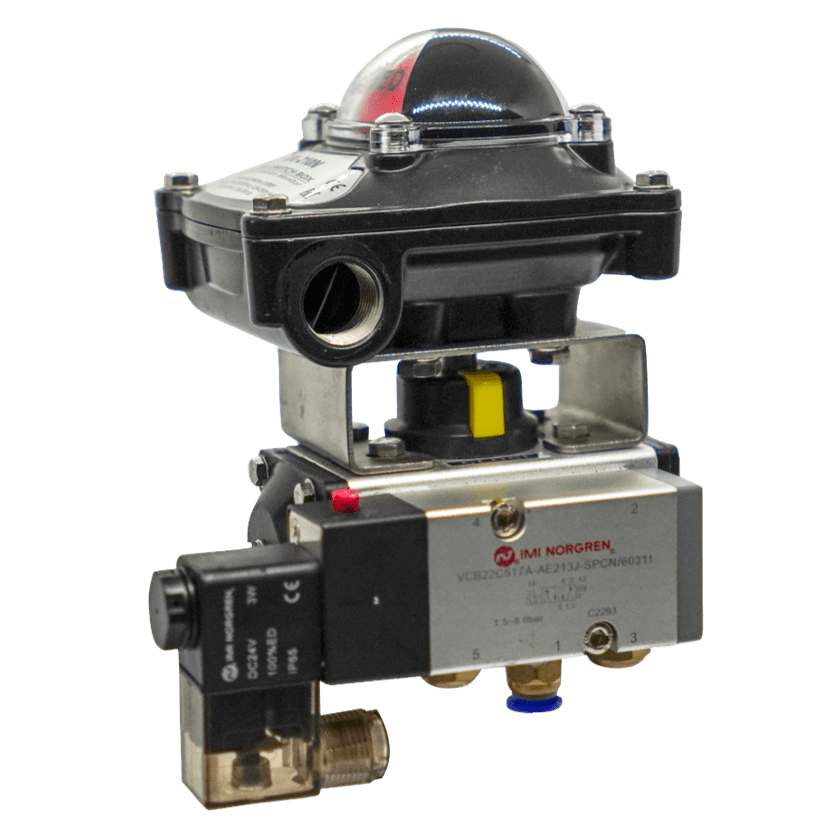

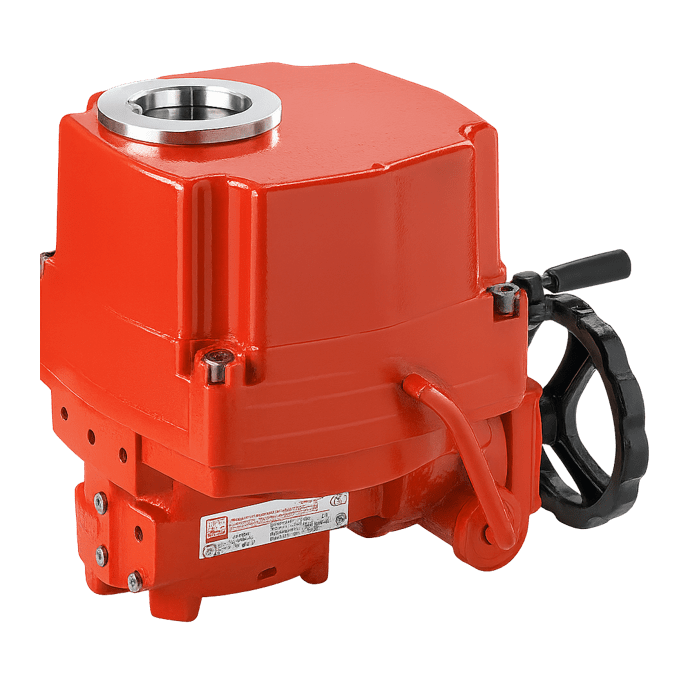

Automation Option & Accessories

Pneumatic Actuator

(Single Acting / Double Acting)

Electric Actuator

Flow Capacity

Cv = 9.2 to Cv = 1020

Pressure Rating

Full Bore

2000psi ¼” – 1”

1500psi 1 ¼” – 2”

1000psi 2 ½” – 4”

Reduced Bore

2000psi ½” – 1”

1500psi 1 ¼” – 2”

1000psi 2 ½” – 4”

Key Features

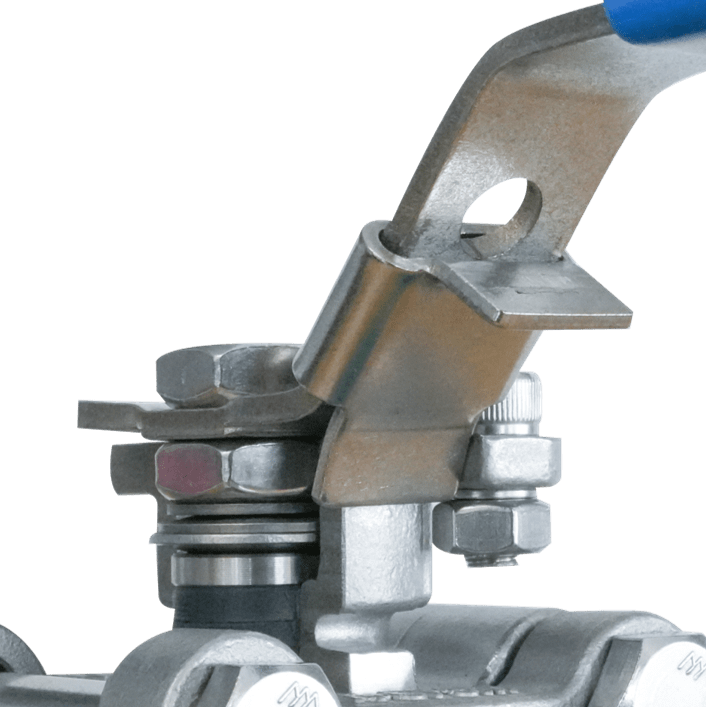

- Superior Live Loaded Packing System

- ISO 5211 Mounting Pad (Bracket Required)

- Blowout-Proof Stem

- Dual Anti-Static Devices

- Fire Safe Design

Performance Testing

Shell Test

Seat Test

Fire-safe Tested

Hydro Test

Anti-static Test

Application Versatility

Built to Perform Across Industries

Our valves are engineered to deliver consistent performance across a wide range of demanding industrial environments.

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Available Options

Enhance Your Valve Functionality

Choose from a range of accessories designed to extend performance, simplify operation, and suit specific installation needs.