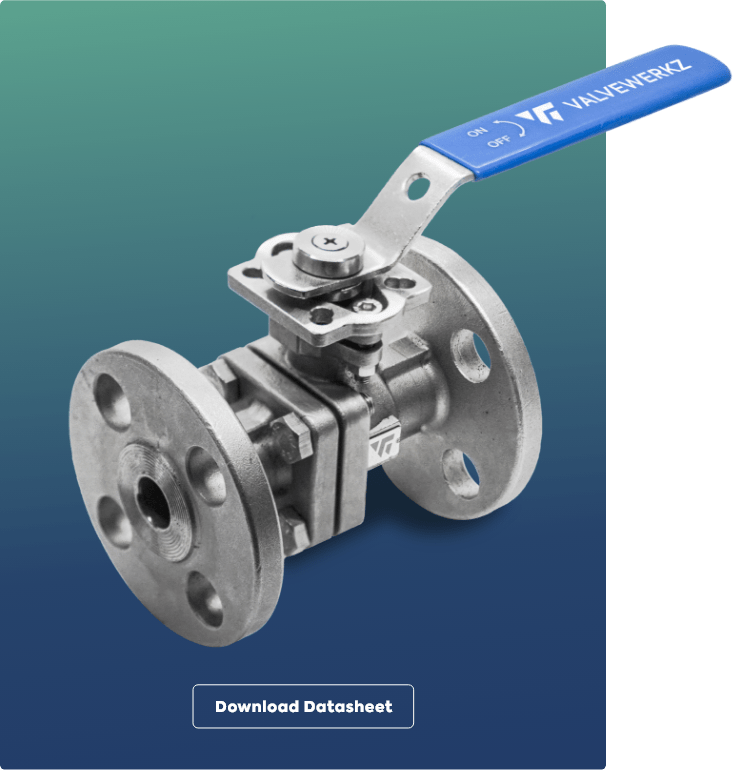

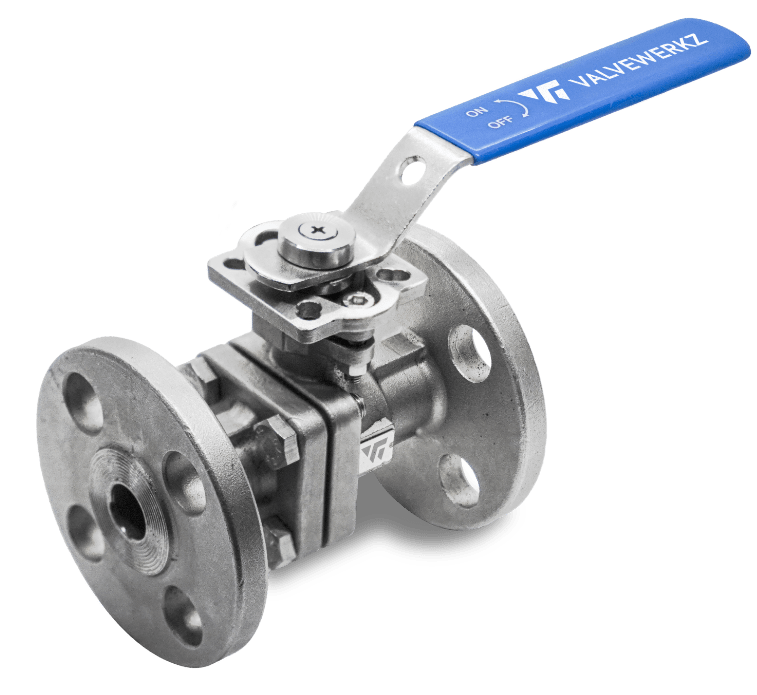

Flange Ball Valve

203 Series Ball Valve

Engineered for high performance and process-critical applications.

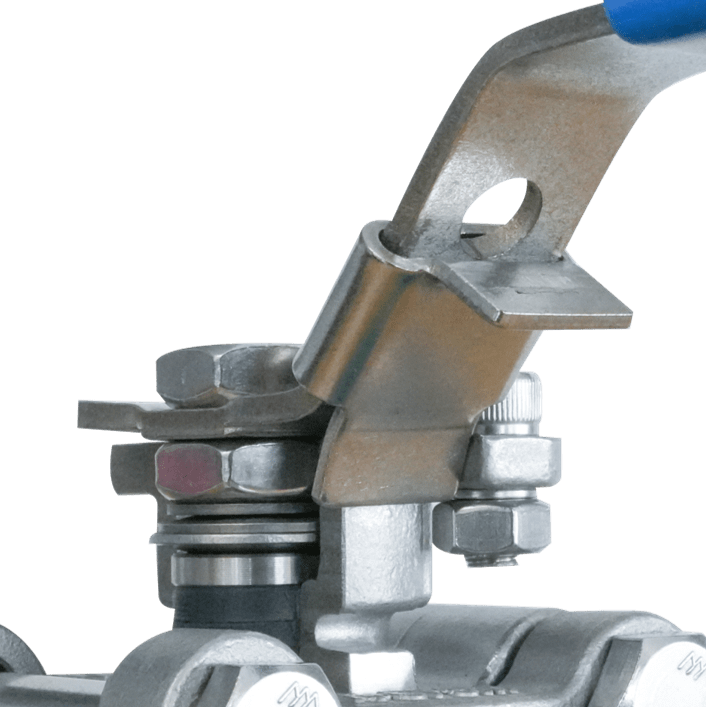

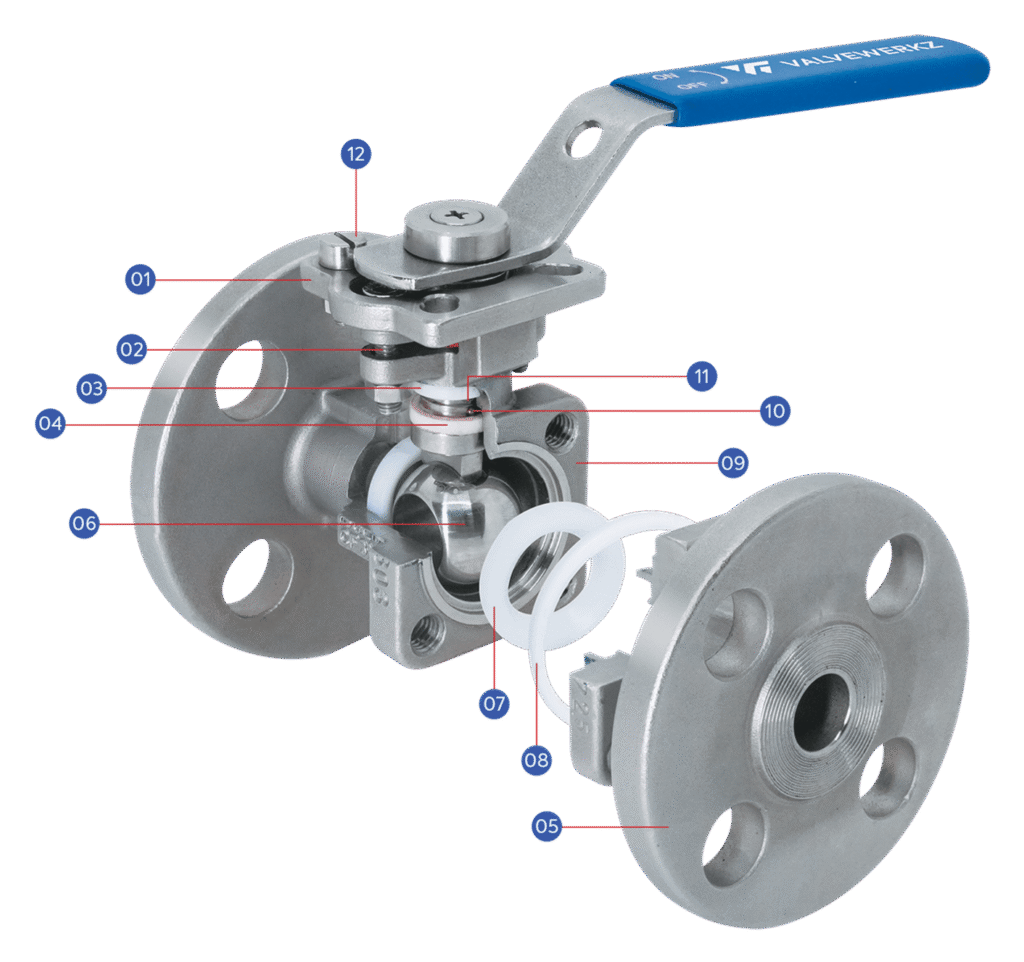

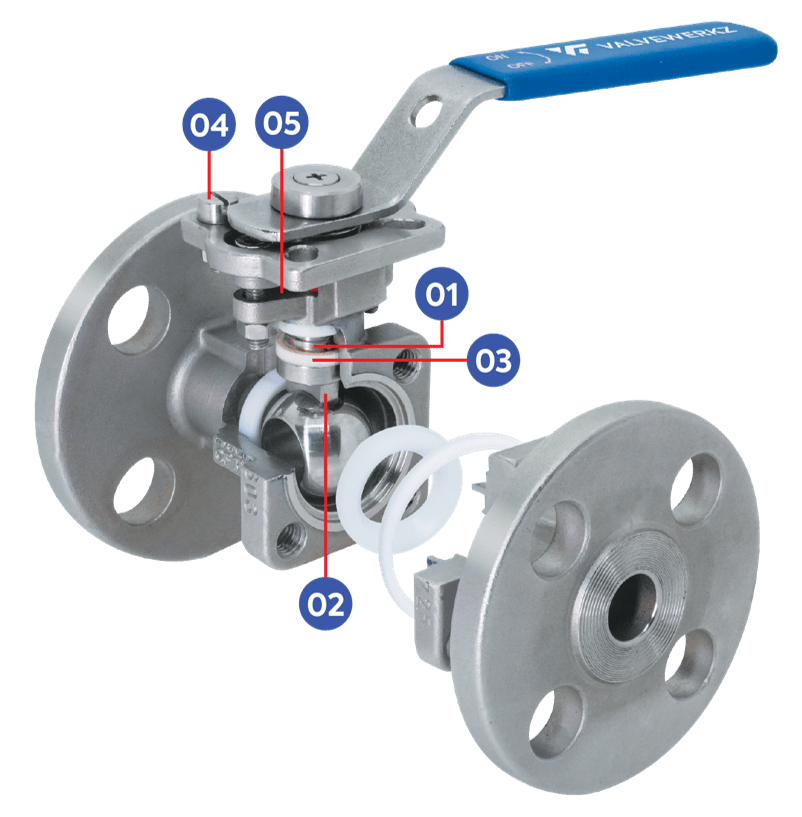

What’s Inside Matters

Engineered for Performance

Every part is designed for durability, precision, and reliability under pressure. From anti-static safety to stem seal integrity, each component plays a critical role in long-term valve performance and system safety.

Part Name

1. ISO5211 Direct Mounting Pad

2. Adjusting Bolt

3. V-Ring Packing

4. O-Ring

5. End Cap

6. Ball

7. Seat(Pressure Relief Groove)

8. Body Gasket

9. Body

10. Anti-Static Device

11. Belleville Washer

12. Stop Lock Block

What’s Inside Matters

Engineered for Performance

Its robust design supports high pressure and temperature service, while full-port construction minimises flow resistance. With anti-blowout stem design and fire-safe capabilities, it’s ideal for demanding industries such as petrochemical, chemical, and refining.

01. Blow-Out Prevention

Integral stem shoulder design prevents blow-out and leakage, ensuring safe and reliable performance.

02. Anti-Static Protection (Dual Anti-Static Device)

Dual anti-static system minimises the risk of safety hazards caused by static electricity.

03. Reliable Stem Sealing

V-ring packing with a primary pyramidal stem seal delivers long-lasting and effective sealing.

04. Misoperation Prevention

Built-in limit device prevents accidental or incorrect valve operation.

05. Adjustable Hidden Gland

Stem packing can be tightened to stop leakage without removing the actuator, reducing downtime.

203 Series

The 203 Series Ball Valve is a high-performance, flanged-end valve engineered for process-critical applications requiring secure connections and consistent sealing.

Specifications

Design

2-Piece Body

Full Bore

Body Material

Carbon Steel

SS304

SS316

Ball Material

SS316

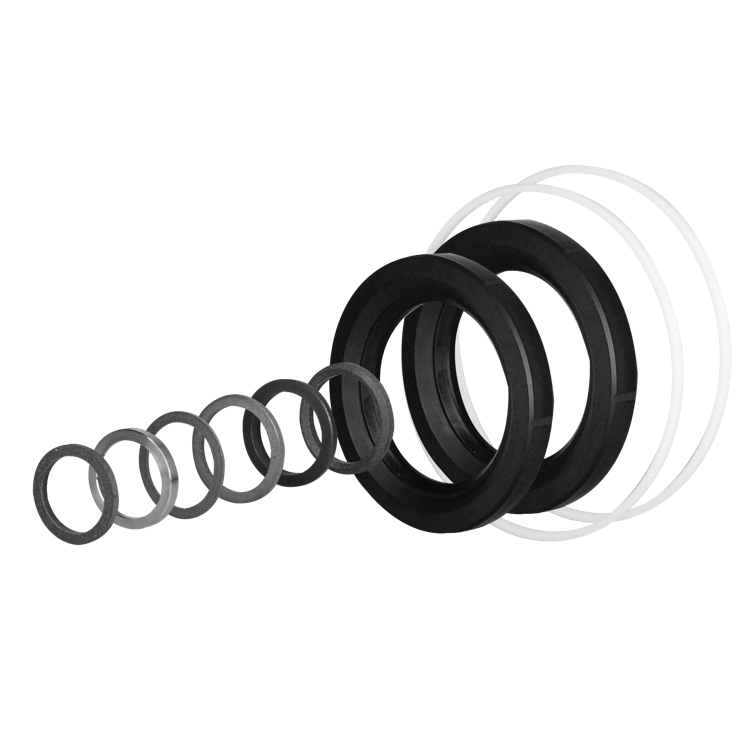

Seat Material

RPTFE

25% Carbon filed PTFE

50% SS filled PTFE

PEEK

Connection

ANSI (ANSI 150 / ANSI 300)

DIN (PN16 / PN40)

JIS (JIS-10K / JIS-20K)

Size

DN15 (½˝) to DN150 (6˝)

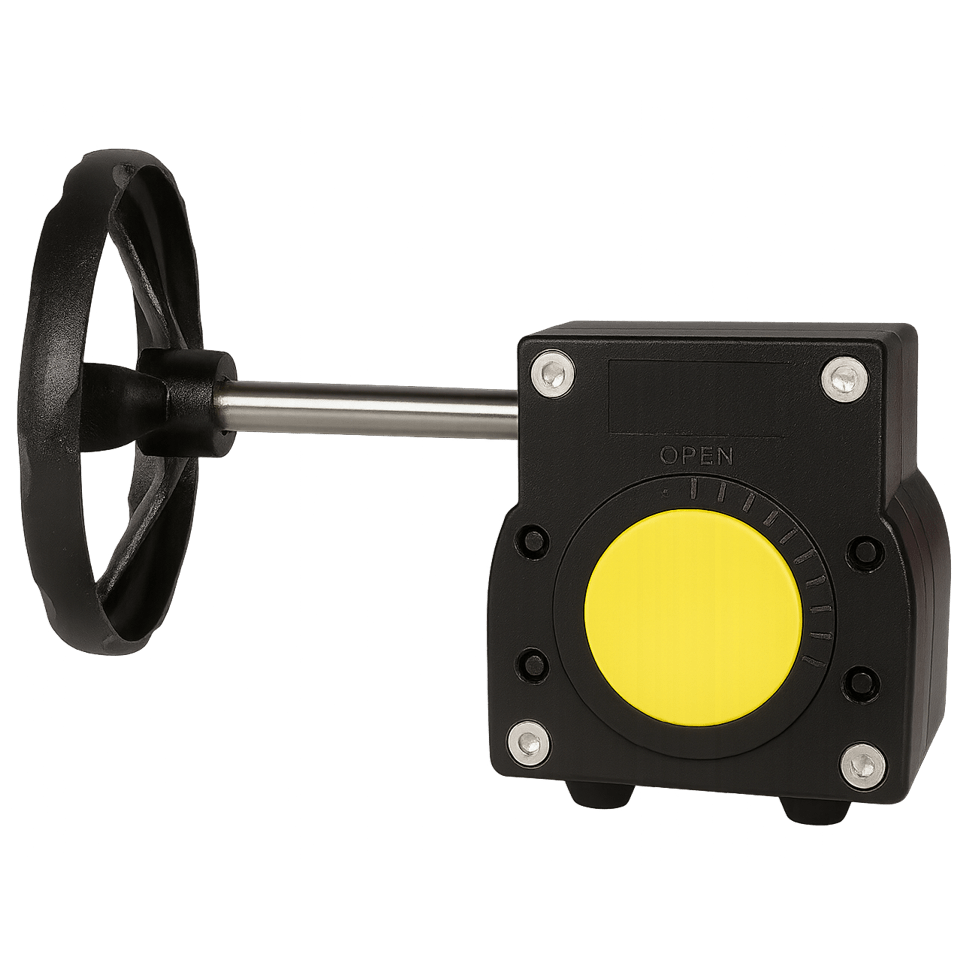

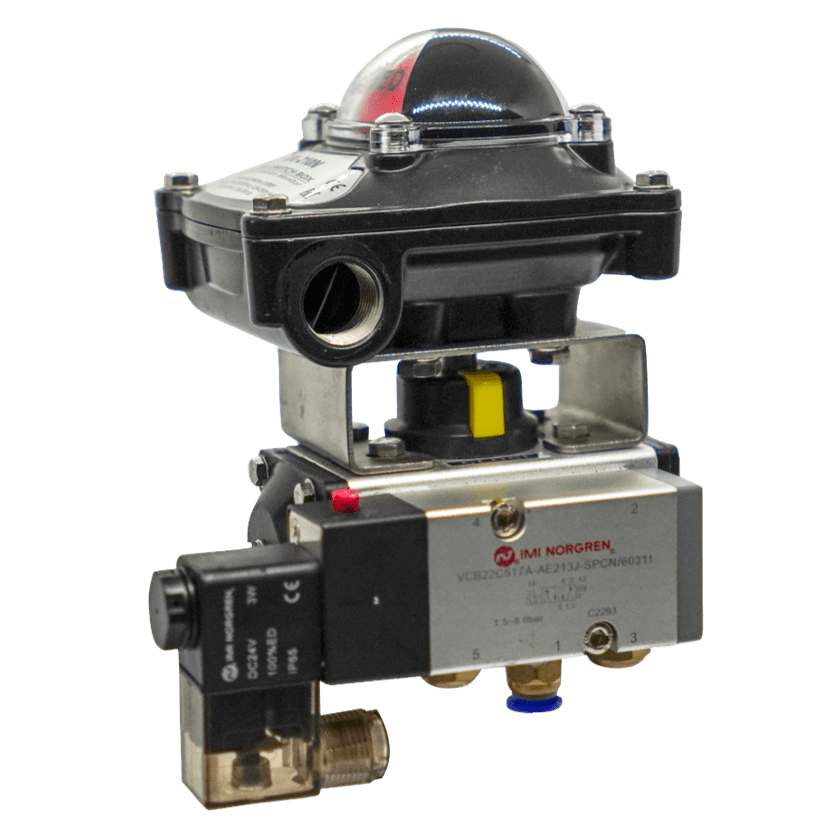

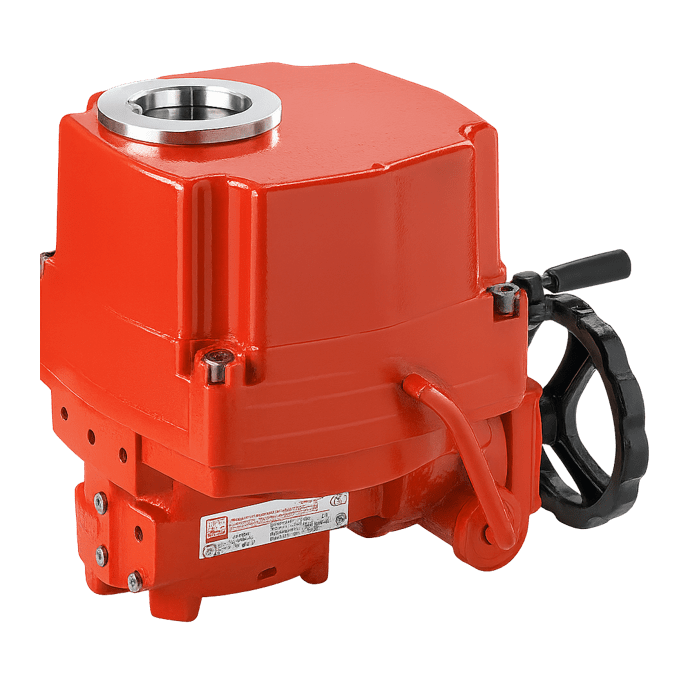

Automation Option & Accessories

Pneumatic Actuator

(Single Acting / Double Acting)

Electric Actuator

Flow Capacity

Cv = 15 to Cv = 5150

Pressure Rating

ANSI (ANSI 150 / ANSI 300)

DIN (PN16 / PN40)

JIS (JIS-10K / JIS-20K)

Key Features

- Superior Live Loaded Packing System (V-ring Packing)

- ISO 5211 Mounting Pad

- Blowout-Proof Stem

- Dual Anti-Static Devices

- Misoperation Prevention

- Fire-Safe Seal Design

- Adjustable Hidden Gland

Performance Testing

Shell Test

Seat Test

Hydro Test

Anti-static Test

Application Versatility

Built to Perform Across Industries

Our valves are engineered to deliver consistent performance across a wide range of demanding industrial environments.

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Available Options

Enhance Your Valve Functionality

Choose from a range of accessories designed to extend performance, simplify operation, and suit specific installation needs.