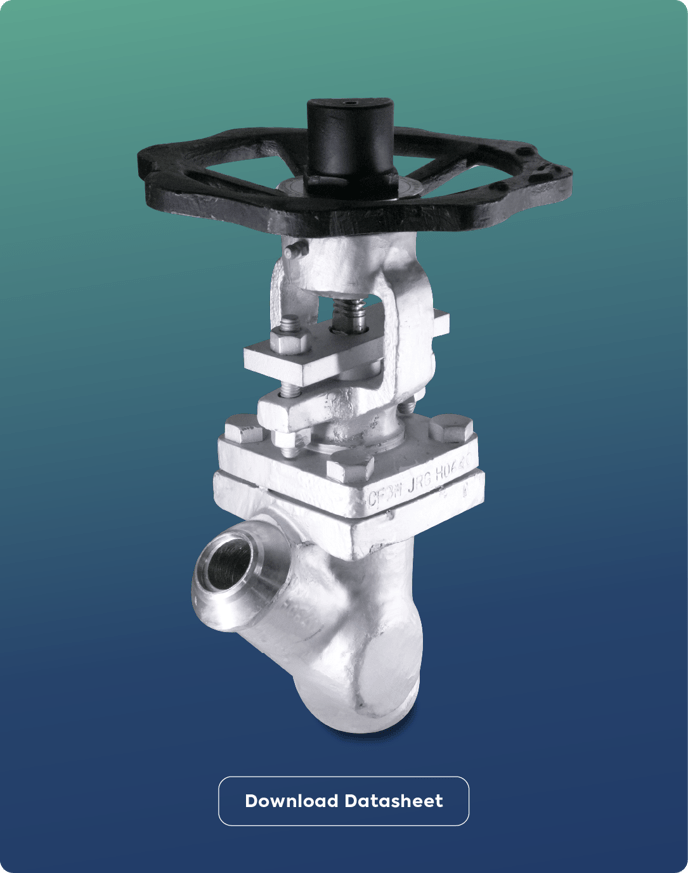

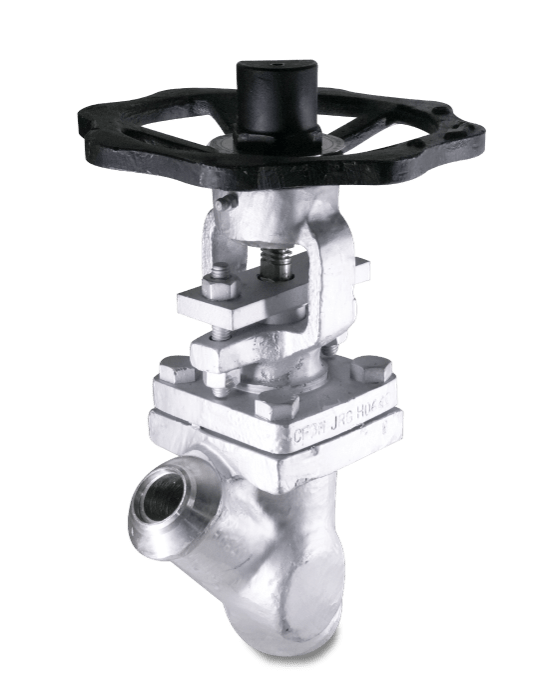

Bellow Seal Globe Valve

GL26 Series (Y-Type)

Engineered for thermal oil and other critical process isolation.

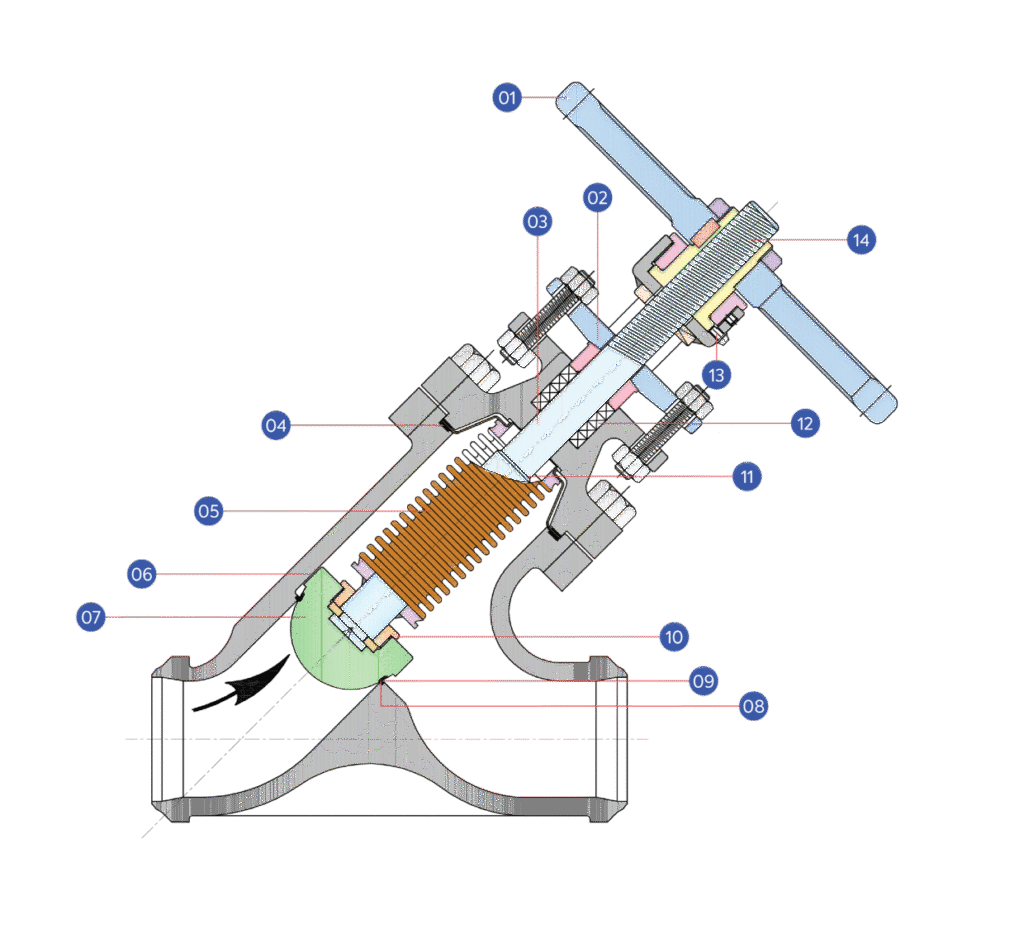

What’s Inside Matters

Engineered for Performance

The GL26 Series combines a precision-guided disc, corrosion-resistant internals, and a fully sealed bellows system to deliver dependable isolation under extreme temperatures.

01. Non Rising Hand Wheel

- Ideal in restricted spaces

02. Ease of operation for Secondary Packing

- Ease for replacing packing

- Improves proper sealing

03. Non Rotating Stem

- High reliability

- Twist of bellow is avoided

- Longer packing life

04. Body-bonnet Joints

- Tongue and groove arrangement

- No gasket slip possible, long service life

05. Multiply Bellows

- High service life

06. Guided Plug

- Body bore guided plug design

07. Throttling Type Plug Design

08. Hardfacing or Stelliting

- Increased service life

09. Integral Body Seat

- Avoid leak through seating

10. Plug and Stem Connected by Stem Nut

- Provides 360° rotation of plug

11. Back Seat Arrangement on Stem

- Additional tertiary safety

- Anti-blow out under line pressure

12. Downstream Safety Gland Packing with Graphite

- Additional reliability against bellow failure

13. Provision for Lubrication on Yoke Sleeve

- Ensures smooth operation

14. ACME Stem Thread

- Longer service life

GL26 Series

The GL26 Series Bellow Seal Globe Valve (Y-Type) is designed for reliable shut-off in thermo oil and high-temperature process lines.

Specifications

Design

Y Type

Body Material

Cast Iron

Forged Steel / A105

Ductile Iron

St. St. 304

Cast Carbon Steel

St.St 316 / 1.4571

Plug Material & Design

Plug:

St. Steel 1.4021 + Hard Faced 13% Cr

Plug Design:

1. Parabolic (For regulating)

2. Conical (For On Off)

3. Balancing (For 5” and above, high pressure)

Seat / Bellow Material

321 Ti

St.St 304

St.St 316 / 1.4571

Hastelloy C

Connection

BSPT – Tappered

NPT

Socket Weld

Flanged End

Butt Weld

Size

DN15 (½”) to DN150 (6”)

Automation Option & Accessories

N/A

Flow Capacity

For Standard Plug:

KVS = 4.8 – 1691

For Throttling Plug:

KVS = 4.36 – 1410

Pressure Rating

ANSI 150

ANSI 300

ANSI 600

ANSI 900

PN16

PN25

PN40

Key Features

- Non Rising Hand Wheel

- Ease of operation for Secondary Packing

- Non Rotating Stem

- Body-bonnet Joints

- Multiply Bellows

- Guided Plug

- Throttling Type Plug Design

- Hardfacing or Stelliting

- Integral Body Seat

- Plug and Stem Connected by Stem Nut

- Back Seat Arrangement on Stem

- Downstream Safety Gland Packing with Graphite

- Provision for Lubrication on Yoke Sleeve

- ACME Stem Thread

Performance Testing

Hydro Test

Air Leakage Test

Application Versatility

Built to Perform Across Industries

Our valves are engineered to deliver consistent performance across a wide range of demanding industrial environments.

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Palm oil and oleochemical lines

General manufacturing

Water and wastewater pipelines

Power plant steam isolation

Chemical and blending applications

Available Options

Enhance Your Valve Functionality

Choose from a range of accessories designed to extend performance, simplify operation, and suit specific installation needs.